LOGIFORM Pipe and Joint system

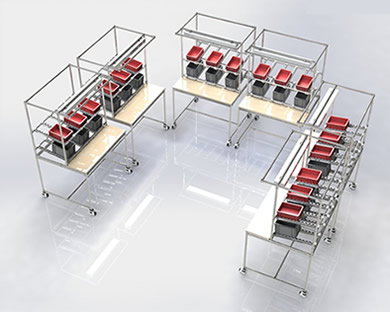

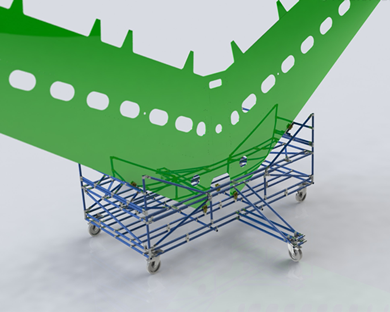

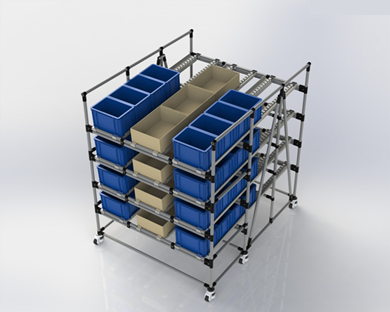

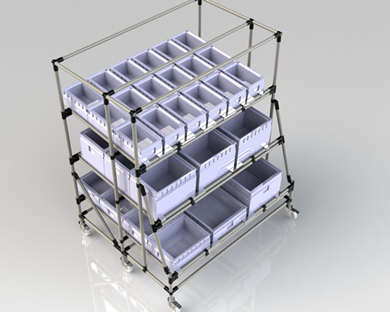

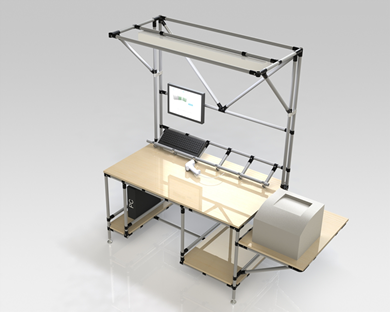

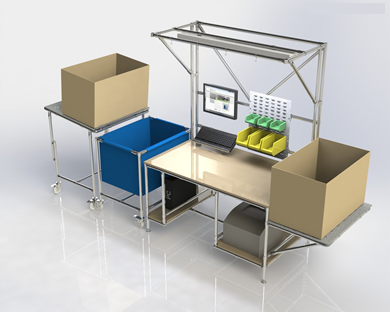

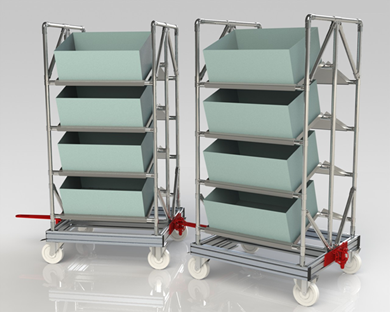

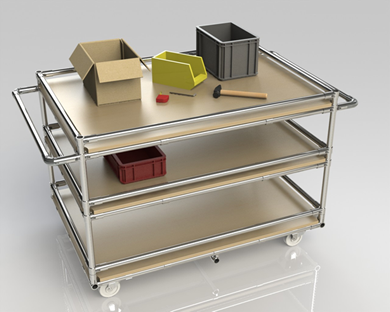

LOGIFORM is a versatile modular tube connection system consisting of steel tubes, roller tracks , easy to assemble steel joints and a wide range of parts and accessories.

The system is designed for a variety of applications, including assembly lines, production and packing stations, storage and transport solutions.

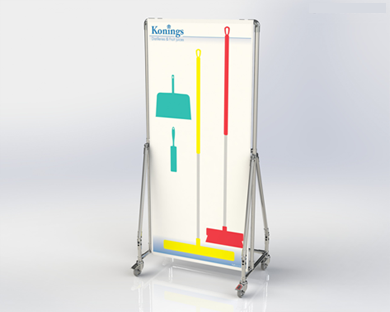

Other applications include exhibition stands, commercial, educational and institutional displays and settings.

Pipe and Joint System Advantages

- Quick to implement

- Easy to use

- Designed and purpose built to meet exact operational requirements

- Enhanced design can improve the ergonomics of an operation

- Assistance in efficient production methods

- Easy to modify as products and processes develop within the company

- Reusable when a project is complete

- Solutions can be designed and built in-house

- Environmentally friendly

- Virtually maintenance free

- Numerous colours are available to aid colour coding and improve aesthetics

- Stainless steel tube ESD (Inherently conductive)

- ESD plastic coated tube is available

- A cost-effective solution

- Various pieces of equipment can be made from stock material avoiding the need for order processing for each individual item required

- The Pipe and Joint System can be fully integrated into continuous improvement programmes providing hardware to meet company goals

- The pipe and joint system can be used as part of the company’s lean implementation and continuous improvement plan